Brand Name: TiBright

Model Number: FB102C

Place of Origin: Shandong, China (Mainland)

Please check out our website: www.tibright.com

Using flux paste can help you save time and material comparing to using the mixture of flux powder and water. The experience have shown that to make 1 kg of fine brazing paste, one might need to use 1.5 kg powder due to the waste and non-even distribution.

| Classification | Character | Application | |

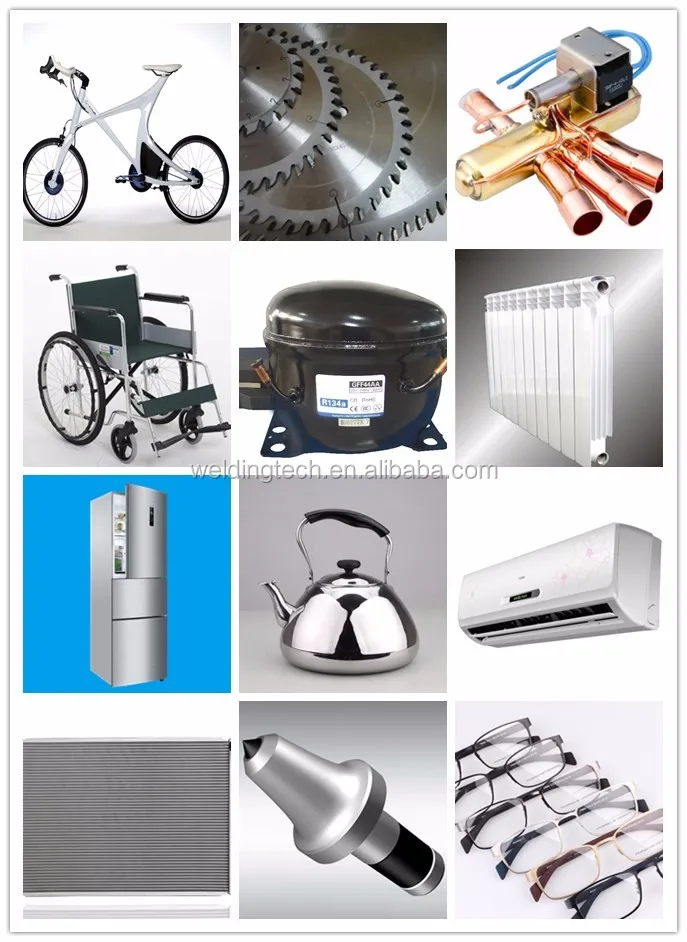

| FB102C-11 | General purpose & Common used silver brazing flux paste, brazing with silver base filler metals, for brazing copper and copper alloy; steel and stainless steel; carbides; PCD etc. | Common used at tube of air condition and refrigerator, valve, compressors for air condition, gas heat water heater, stainlessvacuum cups, motor, wiring, cut tool, glasses etc. |

|

| FB102C-21 | Lower corrosive, good fluidity, brazing with silver filler metals for brazing copper and copper alloys, copper and Bundy pipe, copper and stainless steel. | Good brazing results at hydrant, valve, refrigerator tube, kitchenware, hardware and glasses. |

|

| FB102C-31 | Good fluidity, high active action when brazing carbides, high strength at joint gap. | Current application is brazing carbidescutting and tools, also use for brazing kitchenware. | |

| FB102C-41 | Better performance than FB102C-21, mainly used for brazing steel or stainless steel and copper. | Current application is brazing refrigerator tube, glasses, vacuum cups,hydrant, valve, hardware and so on. |

|

| FB102C-51 | Long time active and lower temperature melting point. Brazing with silver alloy for brazing copper and copper alloy, steel and stainless steel. | Main application is glasses, Refrigerator tube, hydrant, valve etc. |

|

| FB102C-61 | Long time active and lower temperature melting point. Brazing with silver alloy for brazing copper and copper alloy, steel and stainless steel. | Glasses, compressors of refrigerator, Automotive parts, stainless valve, stainless vacuum cups, kitchenware etc. |

|

| Classification | Color | Character | Application |

| FB102C-14 | Brown |

They can be easy to filter and clear up the metal oxide,

Also dissolve oxide, suitable for welding stainless steel, high temperature-tolerate alloy, titanium, nickel and other materials. |

At present, very popular among the glass line, and be commended in automatic welding for automobile parts, food processing equipments, medical apparatus. Besides, also can be used in the kitchen tools, valve, water faucet, keep-heating bottle and so on.

|

| FB102C-15 | Black | ||

| FB102C-24 | Brown |

Better liquidity and wetting ability than the FB102C-14, FB102C-15.

|

At present, very popular among the glass line, and be commended in automatic welding for automobile parts, food processing equipments, medical apparatus. Besides, also can be used in the kitchen tools, valve, water faucet, keep-heating bottle and so on.

|

| FB102C-25 | Black | ||

|

FB102C-44

|

Brown

|

It is the No.1 for welding stainless steel, and contains effective surface activity agent, has the ability to clear away the stainless steel oxide insistently, so you can get the bright and clear high quality weld joint.

|

Same as the above, but most suitable for welding the high quality stainless steel.

|

The surface of the parts should be well treated and oxidation layer should be removed as much as possible. Brazing wires can be dipped into the paste to get the paste attached. Also the paste can be dispensed with syringes, and brushes. Another way is to spray the paste in a very small concentration and low viscosity.

Yantai TiBright Welding Materials Co. Ltd., founded in 2000, is a professional developer and international supplier of inclusive brazing materials, equipment, and consultant. TiBright has hundreds of products for different applications. Customized products are also available for specific purposes.

When choose from our product library, please check out our recommended product list, If you have any questions, please let us know, We will try our best to satisfy your inquiry. Sometimes we need our customers to try different samples to make the perfect decision. Generally, we need to know the following information to choose a right product for you.

1. Materials of your parenting parts (to-be-brazed parts).

2. Heating methods. (eg. flame, induction, vacuum furnace etc. )

3. Atmosphere of application. (eg. room air, protective inert gas, reductive gas, vacuum, etc.)

4. Dimensions of your parts. Photos or graphs are preferred. (Different dimensions require different procedures.)

5. Current solution. (eg. brazing materials, equipment, procedures, etc.)

6. The reasons of searching new solution. (eg. price, strength, applicability, etc.)

7. Industry of your application. (Help us refer to similar examples.)