Brand Name: TiBright

Model Number: FB2 FB5

Place of Origin: Shandong, China (Mainland)

A2RCD077 aluminium brazing water soluble flux paste polishing

Please check out our website, www.tibright.com

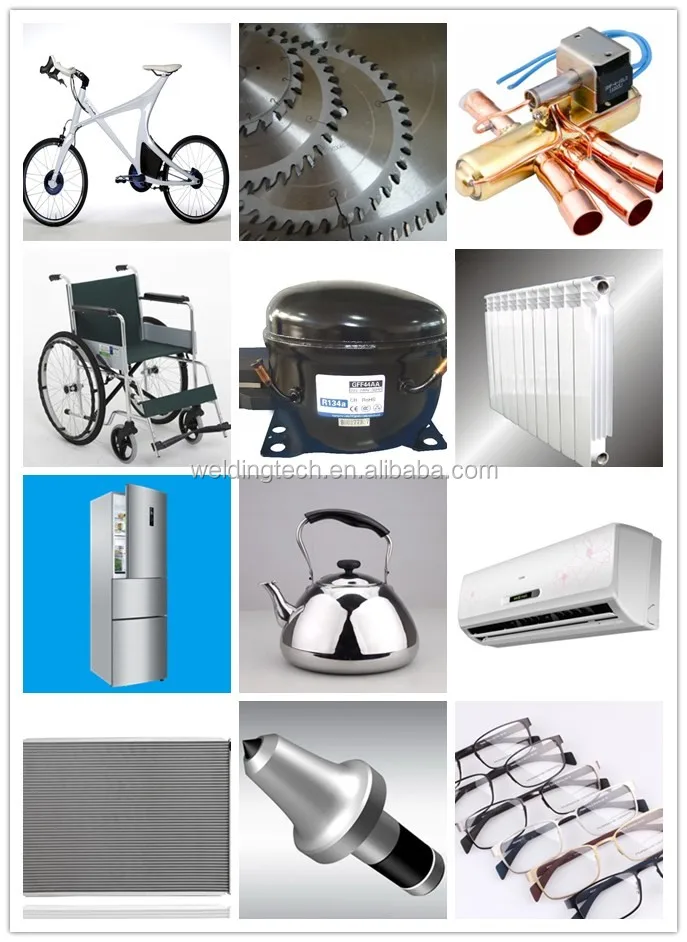

Product Usage |

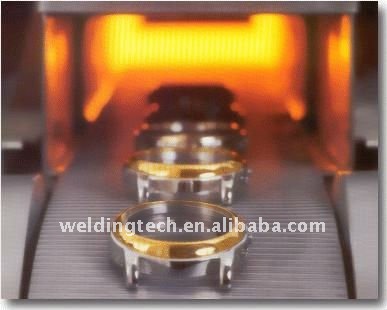

Aluminum brazing flux paste can work together with aluminum or zinc based brazing filler metals on aluminum, aluminum alloy, copper alloy at the temperature range of 450-600°C in frame brazing, induction brazing, electrical resistance welding, furnace brazing, and so on. It is a certified fine replacement of the flux paste known as 0726 paste from Germany. |

Physical Description |

White paste, granularity ≤ 150um. |

Standard |

JB/T6045-92, Fluxes for Brazing, Zhuang, Hongshou |

Storage |

Keep it in dry and cool place. Protect against damp, inedible. |

Package |

1 kg/can, 1 kg/bag, 40kg/box |

Code |

Activity range(°C) |

Description |

FB201C |

450-660 |

Good fluidity,strong ability in removing oxidation film.Water soluble, no residual left. Recommend for repairement market. |

FB201S-11 |

450-660 |

Good fluidity,strong ability in removing oxidation film.Can be mixed with water to become paste,with good viscosity. Water soluble, no residual left. Recommend for repairement market. |

FB201S-21 |

500-600 |

Good fluidity,strong ability in removing oxidation film.Can be mixed with water to become paste,with good viscosity. Water soluble, no residual left. Recommend for radiator brazing. |

FB205C |

500-600 |

Good fluidity,strong ability in removing oxidation film.Water soluble, no residual left. Recommend for radiator brazing. Better than 201C. |

FB205S |

450-600 |

Best activity for brazing with AlSi12, 4047 filler metal for the best brazing quality the requirements. Water soluble, no residule left. Highly recommend for radiator, bike producer. |

FB206S/C |

450-600 |

Great activity with AlSi12, 4047 filler metal alloy. water soluble, no residule left. Highly recommend for situation of high requirements in powder or paste form. |

FB501S/C |

560-600 |

Superior ability in removing oxidation film. Potassium floroaluminate flux system. Non-water-soluble. Thin residual film remain. Recommend for auto-radiator furnace brazing procedure. |

FB502S/C |

430-600 |

Superior ability in removing oxidation film. Low melting temperature, water washable. Expensive materials with cesium. Recommend for auto-radiator furnace brazing procedure. |

FB503S/C |

520-600 |

Great activity, low temperature, non-water soluble, thin residual film remain, in powder or paste form. |

FB504S/C |

560-600 |

Self flux and no filler metal is needed. Non-water soluble, thin residual film remain, in powder or paste form. |

The aluminum brazing flux has two main types: water soluble, and non-corrosive.

This flux paste is made from flux powder with liquid that remains the quality and visicosity. It can prevent the flux powder from absorbing water from the air.

Because of the solubility this kind of aluminum flux leaves no residual after being rinsed with water after brazing. However, the solution of this kind of flux is highly corrosive to metal materials thus the brazing parts need to rinsed thoroughly.

Another type is called non-corrosive aluminum flux. The most popular flux component is potassium floroaluminate (FB501). TiBright developed a new similar one with lower temeprature FB503. Also, FB502 has the main component of potassium-cesium floroaluminate. This one has low melting temperature (430C), and water soluble. It is also the most expensive one.

There is also a third type flux, FB504, which was developed by TiBright. FB504 has materials which can react with aluminum and generate a active layer on the surface of aluminum. This surface can act as filler metal, which means there is no need for any more filler metal.

Yantai TiBright Welding Materials Co. Ltd., founded in 2000, is a professional developer and international supplier of inclusive brazing materials, equipment, and consultant. TiBright has hundreds of products for different applications. Customized products are also available for specific purposes.

When choose from our product library, please check out our recommended product list, If you have any questions, please let us know, We will try our best to satisfy your inquiry. Sometimes we need our customers to try different samples to make the perfect decision. Generally, we need to know the following information to choose a right product for you.

1. Materials of your parenting parts (to-be-brazed parts).

2. Heating methods. (eg. flame, induction, vacuum furnace etc. )

3. Atmosphere of application. (eg. room air, protective inert gas, reductive gas, vacuum, etc.)

4. Dimensions of your parts. Photos or graphs are preferred. (Different dimensions require different procedures.)

5. Current solution. (eg. brazing materials, equipment, procedures, etc.)

6. The reasons of searching new solution. (eg. price, strength, applicability, etc.)

7. Industry of your application. (Help us refer to similar examples.)